●Low coefficient of friction

●Self-lubrication

●Low temperature resistant

●Corrosion resistant

●Wear Resistant

●Weatherproof

●Excellent chemical resistance

●Light-weight

●High tensile strength

●Good mechanical characteristics

Materials | UHMWPE |

Size | 1000*2000mm,1220*2440mm,or custom |

Processing Method | Mould Pressing |

Thickness | 8mm to 300mm |

Density | 0.93g/cm3 |

Molecular Weight Rate | <0.01% |

Color | black , or custom |

Customized | accept |

●Non-Toxic

●Low coefficient of friction

●Self-lubrication

●Low temperature resistant

●Corrosion resistant

●Wear Resistant

●Weatherproof

●Excellent chemical resistance

●Light-weight

●High tensile strength

●Good mechanical characteristics

●Nuclear reactors, radioactive material storage and transport containers

●Radiation protection equipment

●In nuclear weapons test monitoring, nuclear submarines and aerospace vehicles

●Shielding of neutron sources or reduction of radiation dose in laboratories

●Manufacture of protective facilities and containers to dispose of radioactive waste

●Other industrial applications

| Test Items | Test method | Unit | Value | ||||||

| General properties | DIN 53479 | g/cm³ | 0.934 | ||||||

| Molecular weight | 10 6g/mol | 4.5 | |||||||

| Elongation at break | ISO 527 | % | > 340 | ||||||

| Tensile modulus | ISO 527 | Mpa | 1200 | ||||||

| Yield stress | ISO 527 | Mpa | 27 | ||||||

| Hardness | ISO 868 | Shore D | 67 | ||||||

| Melting temperature | DIN 53736 | °C | 135 | ||||||

| Water absorption | 24h/RT | % | <0.01 | ||||||

| Friction coefficient | 0.01-0.03 | ||||||||

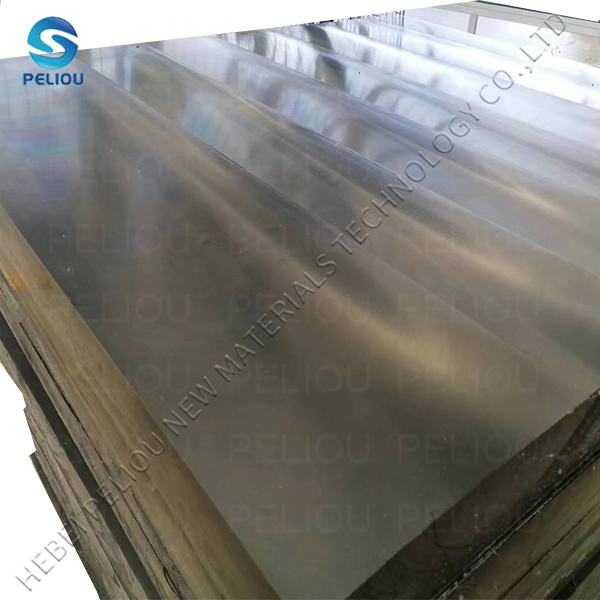

UHMWPE is used where sliding abrasion occurs or where metal parts meet, causing friction or abrasion wear. It is excellent for chute and hopper liners, convey or components, wear pads, machine guides, impact surface and guide rails.

●High abrasion & impact resistance.

●Easily machined.

●Almost completely inert to chemical attacks.

●Zero coefficient of friction.

●Non-caking & sticking.

●Good electrical properties.

●Performs very well in colder temperature applications.

●Maximum temperature: 180°F.

●Meets FDA standards.

●Water absorption < 0.01%.