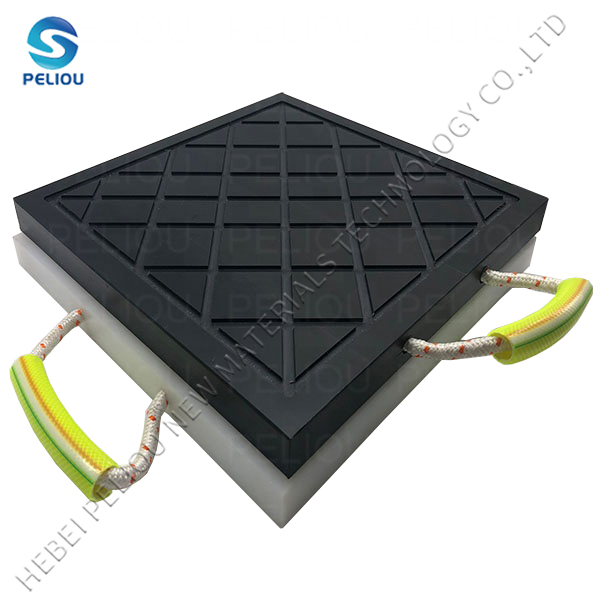

| Size(mm) | Thinckness(mm) | Load(ton) |

| 450*450 | 25 | 25 |

| 600*600 | 25 | 34 |

| 915*915 | 25 | 42 |

| 760*760 | 50 | 38 |

| 1200*1200 | 50 | 63 |

| Customized to your needs | ||

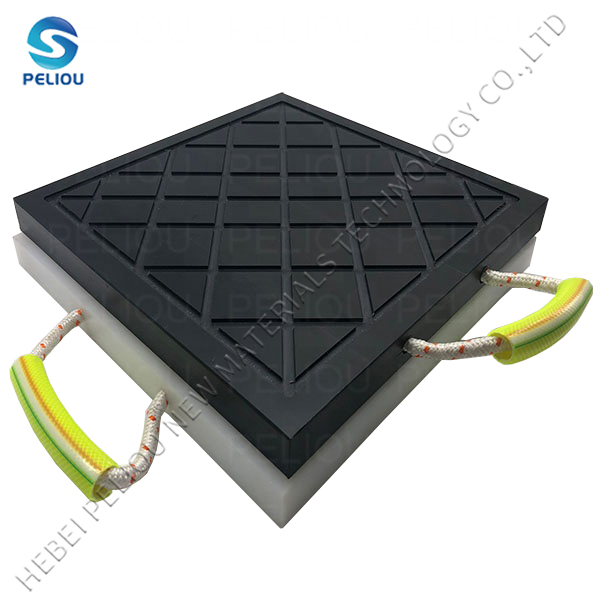

Durability: Outrigger pad have high impact and abrasion resistance and can withstand heavy loads without being easily damaged.

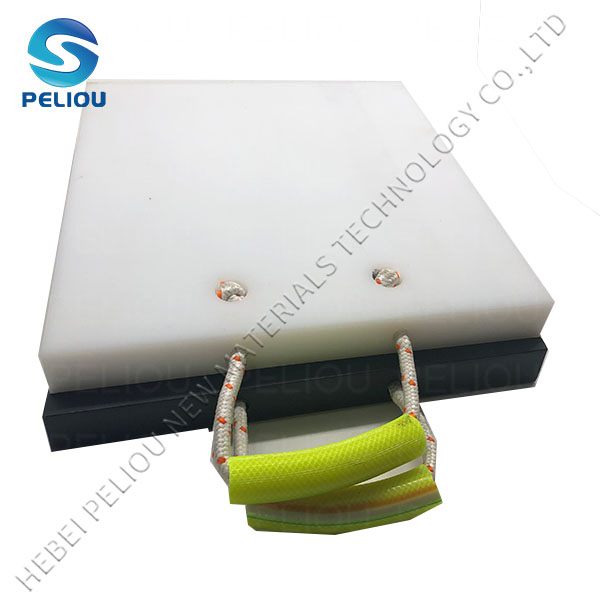

Lightweight: Compared to wood or metal mats, plastic Outrigger pad are lighter, making them easier to handle and install.

Corrosion resistance: Outrigger pad not easily affected by water, oil and chemicals, suitable for wet or corrosive environments.

Easy to clean: Outrigger pad have smooth surface, relatively simple to clean and maintain.

Compressive strength: Outrigger pad can effectively spread the load and reduce the risk of ground damage.

Non-absorbent: Outrigger pad does not absorb moisture, avoiding the problem of rotting wooden mats.

Environmentally friendly: many plastic Outrigger pad can be recycled, reducing the burden on the environment.

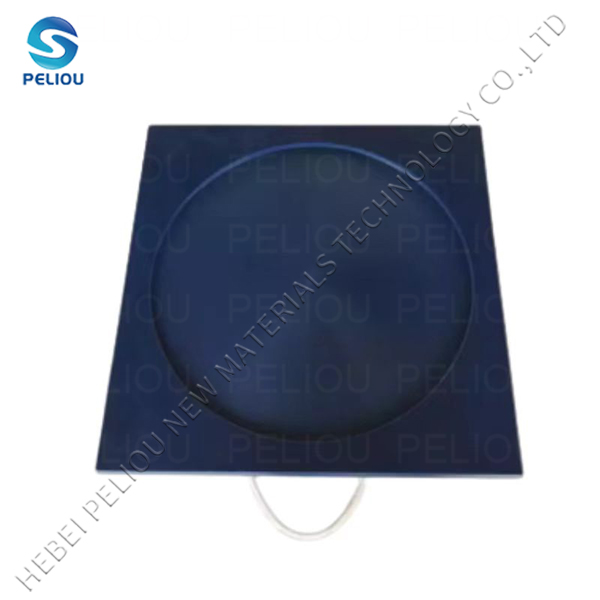

Versatility: Outrigger pad can be customized in different shapes and sizes to suit a wide range of equipment and floor conditions

Durability: Outrigger pad have high impact and abrasion resistance and can withstand heavy loads without being easily damaged.

Lightweight: Compared to wood or metal mats, plastic Outrigger pad are lighter, making them easier to handle and install.

Corrosion resistance: Outrigger pad not easily affected by water, oil and chemicals, suitable for wet or corrosive environments.

Easy to clean: Outrigger pad have smooth surface, relatively simple to clean and maintain.

Compressive strength: Outrigger pad can effectively spread the load and reduce the risk of ground damage.

Non-absorbent: Outrigger pad does not absorb moisture, avoiding the problem of rotting wooden mats.

Environmentally friendly: many plastic Outrigger pad can be recycled, reducing the burden on the environment.

Versatility: Outrigger pad can be customized in different shapes and sizes to suit a wide range of equipment and floor conditions