| Test Items | ASTM | Unit | Value | ||||||

| Density | D1505 | g/cm³ | 0.96 | ||||||

| Melt Index | D1238 | g/10min | 0.5 | ||||||

| HLMI | D1238 | g/10min | --- | ||||||

| Condition A, F50(100% Igepal) | D1693 | h | >500 | ||||||

| Condition B, F50(100% Igepal) | D1693 | h | --- | ||||||

| Tensile Yield Strength,50mm/min | D638TypeIV | Mpa | 26 | ||||||

| Elongation at Break,50mm/min | D638TypeIV | % | >300 | ||||||

| Brittleness Temperature | D746 | ℃ | <-40 | ||||||

| Flexural Modulus, Tangent | D790 | Mpa | 950 | ||||||

| Shore D Hardness | D2240 | - | 65 | ||||||

![]()

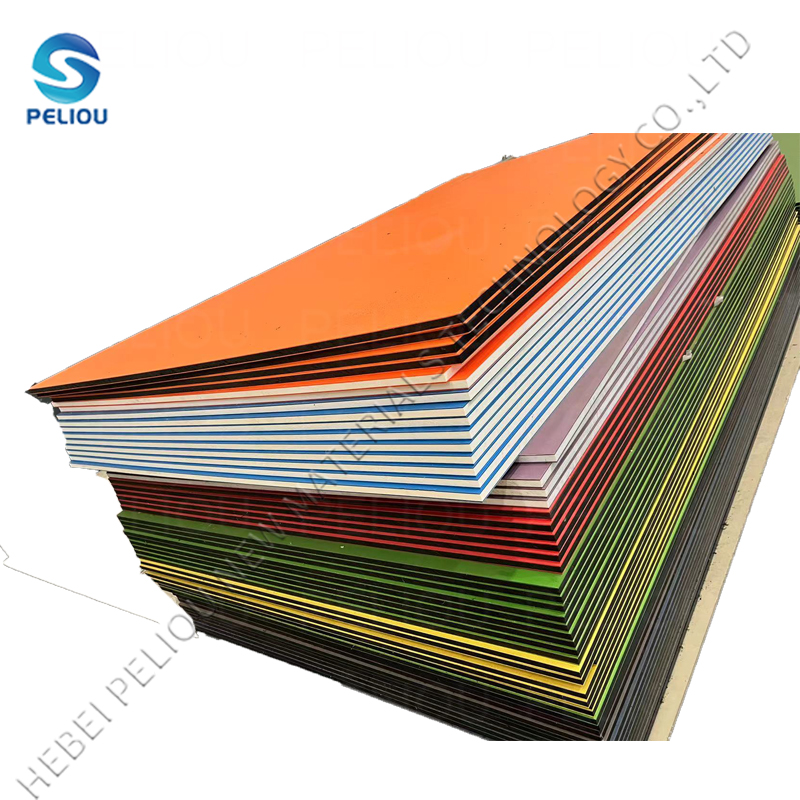

Feature:

High abrasion and wear resistant

Anti-weather & Anti-aging

Self-lubricating & Very low coefficient of friction

Excellent chemical & corrosion resistant

Superior impact resistant , Noise-absorption , Viberation-absorption

High tensile strength

Non-toxic and smell

UV resistance

Flame retardant

Relatively low in water absorption

Light weight & easier to handle and fix