In the world of heavy machinery and construction, stability and safety are of the utmost importance. One of the key components that ensure the safe and efficient operation of mobile cranes is the Crane Outrigger Pad. Designed to distribute the crane’s weight evenly and prevent ground damage or equipment instability, the Crane Outrigger Pad plays a vital role in various industrial applications.

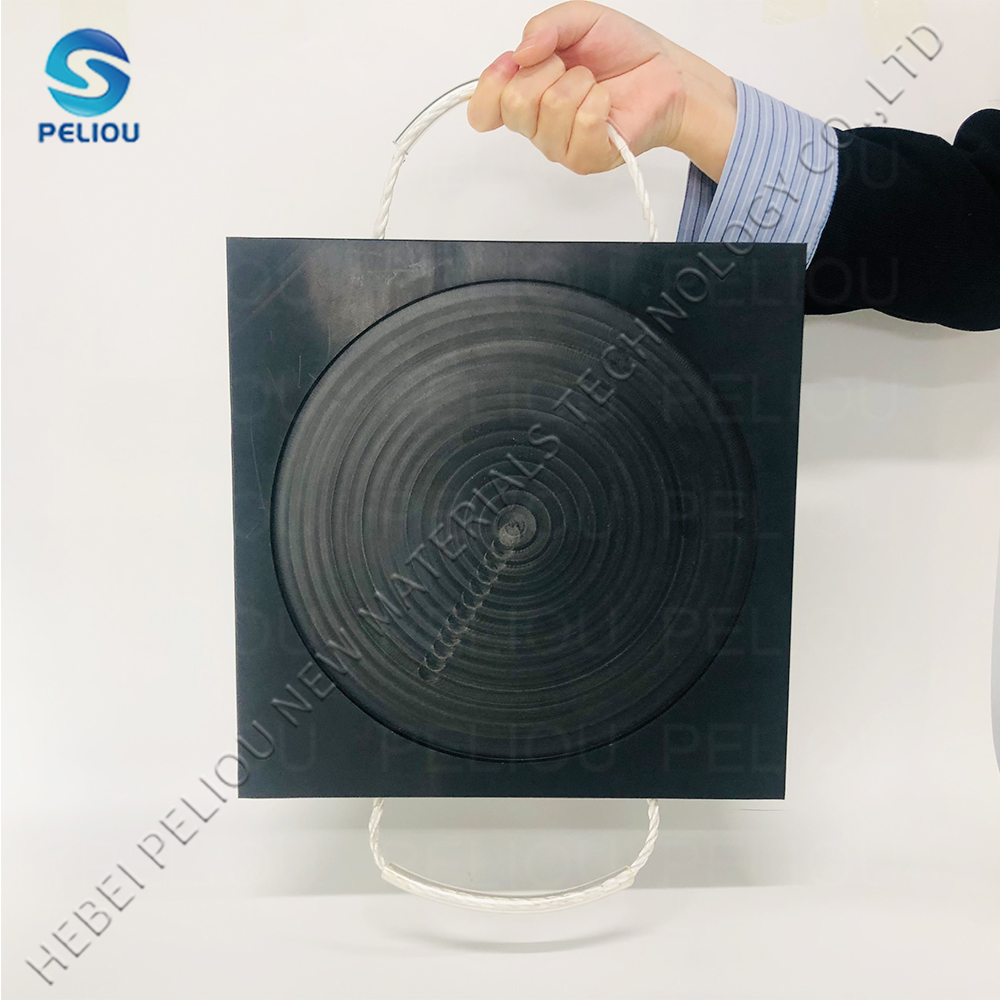

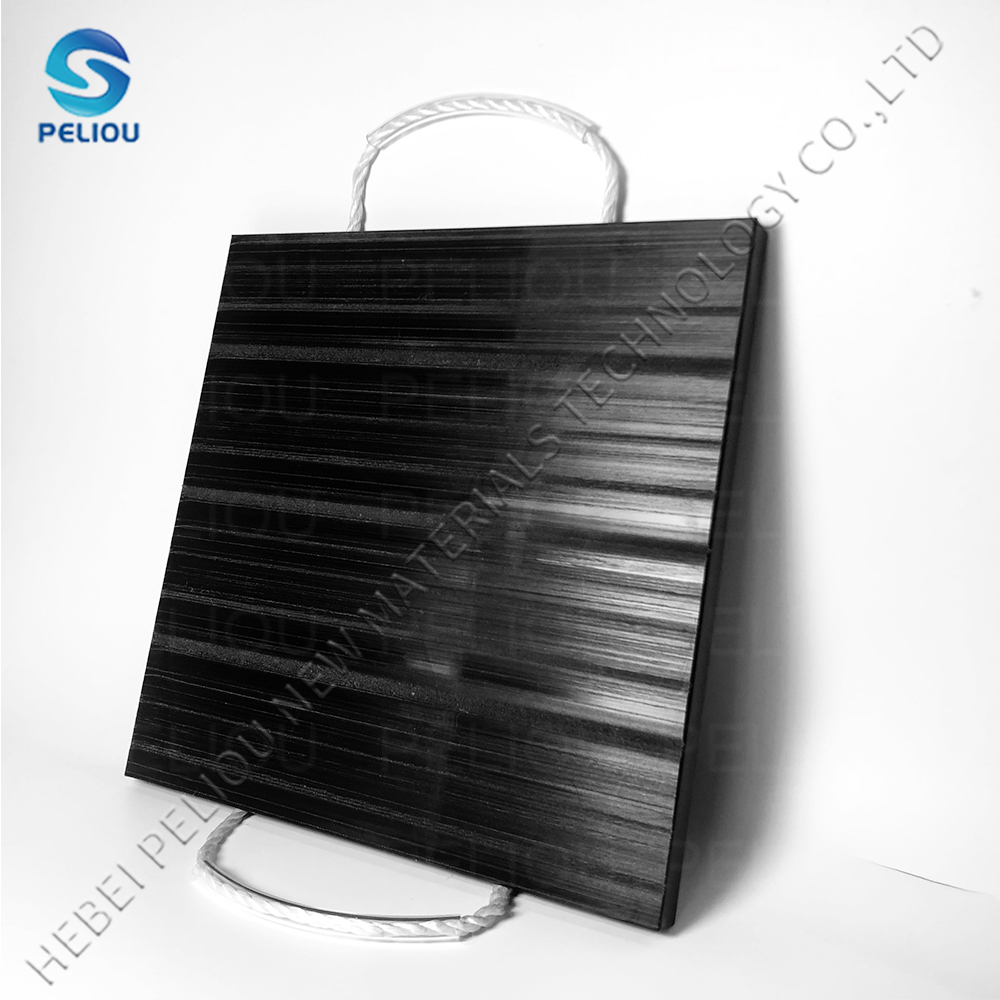

The surface of a Crane Outrigger Pad must be designed to provide maximum traction and durability under various conditions. Common surface treatments include: Anti-Slip Surface: A non-slip finish is essential for maintaining stability. This treatment helps prevent the outrigger feet from sliding, ensuring secure placement. Grooved Surface: Grooves are usually machined by CNC . Making the Crane Outrigger Pad ideal for outdoor and all-weather operations. Diamond Tread Pattern: the diamond tread surface provides excellent resistance to lateral movement. It is particularly effective on inclined surfaces or when the crane needs to be repositioned frequently. Each surface treatment has its advantages, and the choice depends on the terrain and working conditions, making the Crane Outrigger Pad versatile and adaptable to different job sites.

Since Crane Outrigger Pads need to be moved frequently on job sites, their portability is an important design consideration. Handles are incorporated into the design to facilitate easy transport and positioning. The most common types include: Metal Handles: These offer high durability and strength, suitable for heavy-duty pads used in rugged environments. Nylon Rope Handles: Lightweight and flexible, nylon rope handles are user-friendly and ideal for smaller or medium-sized pads. They provide a comfortable grip and are resistant to weather and abrasion. Chain Handles: Chain handles allow for secure attachment to lifting equipment, streamlining the deployment process. By integrating the right handle type, the Crane Outrigger Pad becomes not only safer to use but also more convenient to handle across different applications.