How To Choose The Best HDPE Ground Protection Mats

Ground protection mats are essential tools in various industries to safeguard surfaces from damage and ensure safe operations. Among the different materials available, High-Density Polyethylene (HDPE) stands out due to its durability and versatility.

Reasons why people choose HDPE ground protection mat

1.High abrasion and impact resistance.

HDPE is a high-density plastic that withstands significant weight and stress, making it ideal for heavy machinery and vehicle traffic. This durability helps in preventing soil erosion and surface damage, extending the life of the underlying ground.

2.Suitable for a variety of complex environments

HDPE plastic ground protection mats are resistant to various environmental factors, including moisture, chemicals, and UV radiation. This makes them suitable for diverse conditions, from wet and muddy construction sites to harsh outdoor environments. Their resistance to water and chemicals ensures they perform well even in challenging conditions.

3.Ease of Handling and Installation

HDPE mats are relatively lightweight compared to other ground protection options, which simplifies handling and installation. They often come with interlocking features or connectors that make assembly and disassembly quick and efficient. This ease of use reduces labor costs and minimizes downtime on the job site.

4.Improved Traction and Stability

The surface of heavy duty ground mats is designed to provide excellent traction for vehicles and equipment. This stability reduces the risk of slipping or getting stuck, improving overall safety on the site. Enhanced traction is especially crucial in slippery or uneven conditions, ensuring smooth and secure operation.

5.Cost-Effectiveness

Although plastic temporary road mats may have a higher initial cost compared to some alternatives, their durability and low maintenance needs make them cost-effective in the long run. They are less likely to need frequent replacement or repair, offering better value over time.

How to choose the right HDPE ground protection mat for you

1.Maximum weight the mat needs to hold

Assess Load Requirements Determine the maximum weight and load that the mats will need to support. HDPE mats come in various thicknesses and load-bearing capacities. For heavy machinery or vehicles, select mats with higher thickness and load ratings to ensure they can handle the demands without cracking or bending.

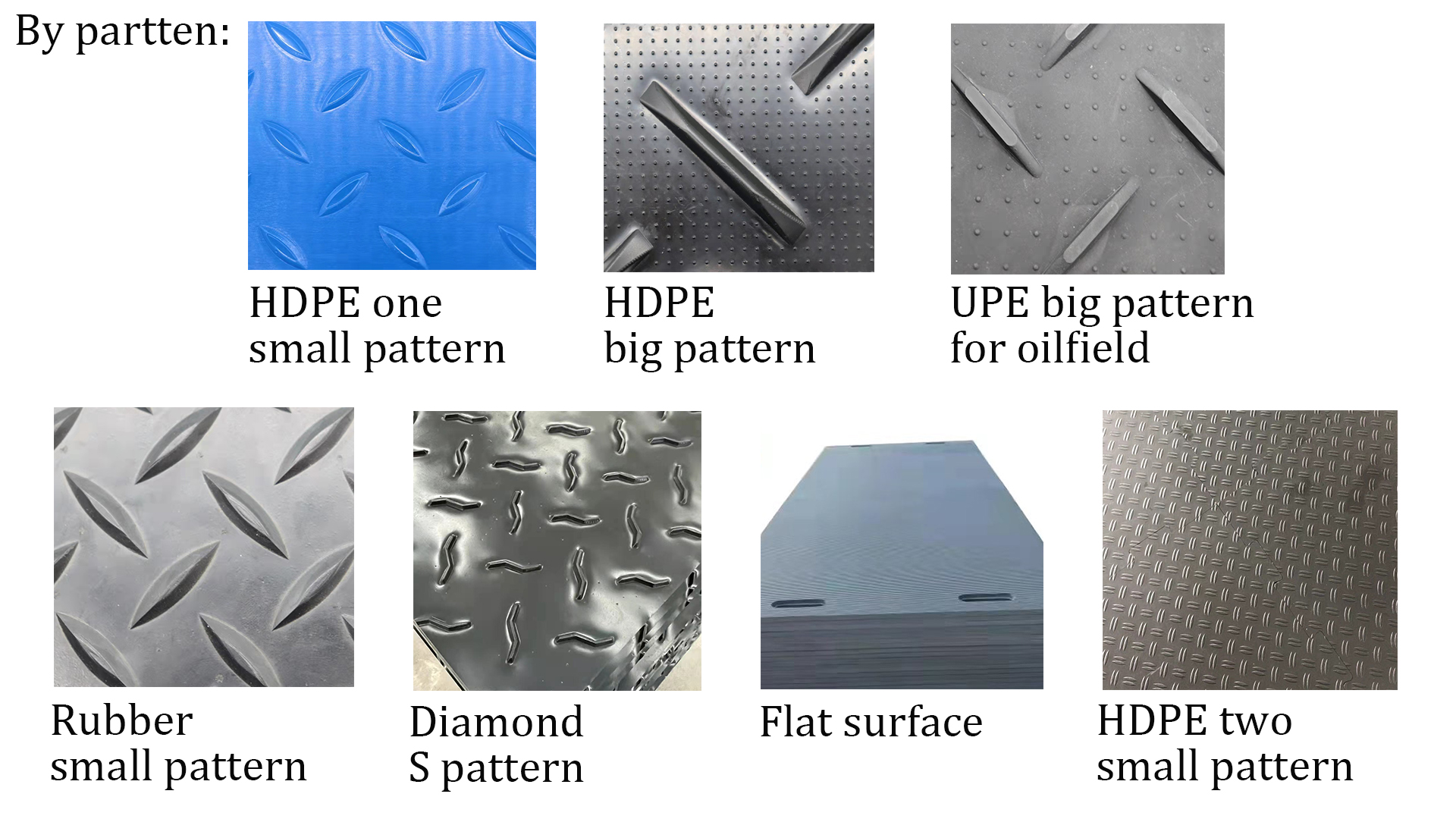

2.Choose the pattern according to the usage scenario

2.Choose the pattern according to the usage scenario

Consider Surface Conditions Evaluate the conditions of the surface where the mats will be used. If the ground is soft or muddy, mats with larger surface areas and a higher load distribution capability are preferred to prevent sinking. For uneven or rocky surfaces, mats with more robust structural integrity and interlocking features may be necessary.

3.Need for enhanced UV and chemical resistance?

Check for UV and Chemical Resistance Ensure that the HDPE mats you choose have appropriate resistance to UV radiation and chemicals if they will be exposed to such elements. This resistance will prevent degradation over time and ensure that the mats maintain their effectiveness in various environmental conditions.

4.Selecting the right connector

Evaluate Dimensions and Connectivity Choose mats with dimensions that suit your project needs and consider how they will be connected. Mats should fit together securely to create a continuous, stable surface. Look for features such as interlocking edges or connection systems that make assembly easier and ensure a seamless surface.

5.How to clean

Review Ease of Maintenance Consider how easy it will be to clean and maintain the mats. HDPE mats typically require minimal maintenance, but ensure that the design and surface texture are conducive to easy cleaning. Smooth surfaces are generally easier to clean compared to textured ones.

6.Whether to use recycled materials

Consider Environmental Impact For environmentally conscious projects, check if the HDPE mats are made from recycled materials or are recyclable themselves. This consideration helps in reducing the overall environmental footprint of your project.

Conclusion

HDPE ground protection mats offer a robust solution for preserving surfaces and ensuring safe operations across various environments. Their durability, resistance to environmental factors, and ease of handling make them a preferred choice for many applications. When selecting the right HDPE mats, consider factors such as load requirements, surface conditions, UV and chemical resistance, dimensions, and ease of maintenance. By carefully evaluating these aspects, you can choose the optimal HDPE ground protection mats that meet your specific needs and contribute to the overall success of your project.