Wear-resistant PE (Polyethylene) strips are widely used in various industrial applications due to their excellent durability, low friction, and resistance to abrasion and impact. These strips are often utilized in environments where material handling and mechanical wear are significant concerns.

Key Features:

1. High Wear Resistance: PE strips are known for their ability to withstand continuous wear and abrasion, making them suitable for high-traffic areas and machinery components.

2. Low Friction: The low coefficient of friction reduces wear on both the PE strip and the opposing surface, improving efficiency and longevity.

3. Chemical Resistance: Polyethylene is resistant to a wide range of chemicals, including acids, alkalis, and solvents, which enhances its durability in harsh environments.

4. Impact Resistance: The material can absorb significant impacts without cracking or breaking, providing reliable performance in demanding applications.

5. Moisture Resistance: PE does not absorb moisture, ensuring stability and performance in wet conditions.

Common Applications:

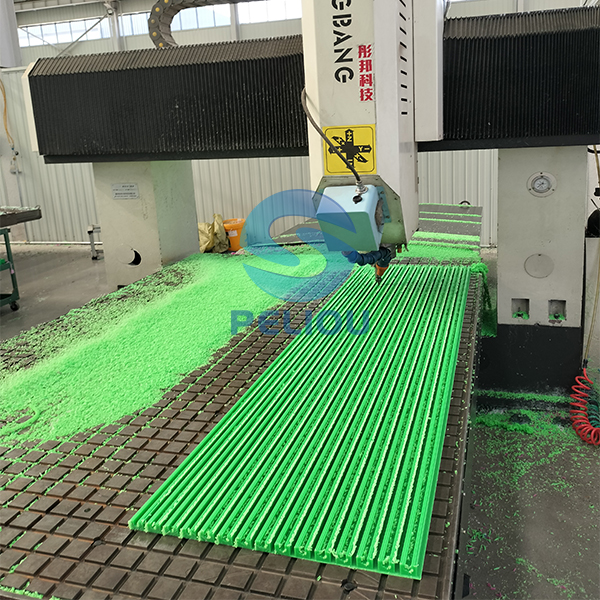

1. Conveyor Systems: PE strips are used as wear strips, guides, and slider beds in conveyor systems to reduce friction and wear on belts and chains.

2. Chutes and Hoppers: Used to line chutes, hoppers, and other material handling equipment to facilitate the smooth movement of bulk materials and reduce sticking and wear.

3. Guides and Rails: Serve as guide rails and tracks in various machinery to ensure smooth movement and reduce wear on moving parts.

4. Protective Linings: Applied as liners in bins, silos, and other storage equipment to protect against abrasive materials and extend equipment life.

5. Bearing and Bushings: Used in applications requiring low friction and high wear resistance, such as bearings and bushings in machinery and equipment.