During the use of PP plastic board, you will find that its quality is affected by density. In fact, this is mainly due to the composition and characteristics of the board. Today, we will take a look at its composition and characteristics.

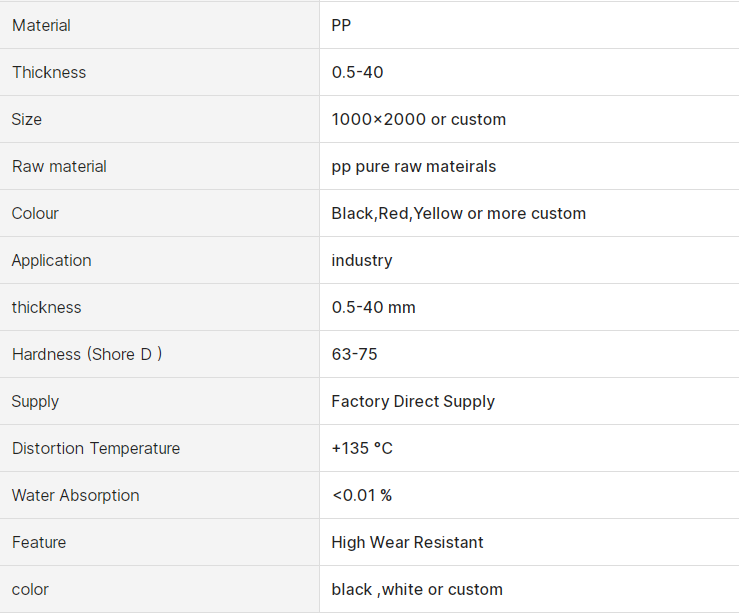

1. PP plastic board is a type of plastic board made by adding various functional additives to PP resin through processes such as extrusion, calendering, cooling, and cutting.

2. It is a semi crystalline material, so compared to similar products, it has higher hardness and melting point. PP will not have the problem of environmental stress cracking.

3. Due to the brittleness of homopolymer type PP at temperatures above 0 ℃, many commercial PP materials are irregular copolymers containing 1% to 4% ethylene, or clamp copolymers with higher ratios of ethylene content. Copolymer type PP materials have lower thermal distortion temperature (100 ℃), low transparency, low glossiness, and low rigidity, but also have stronger impact strength.

4. The composition of PP plastic board determines that its density is good, and its characteristics are also quite good.

Through our analysis above, we have gained a certain understanding of the composition and characteristics of PP plastic board. When we find that its density is too high, we should not be too anxious. We can carefully analyze its characteristics to see if its components are complete, so as to ensure the stable performance of the product in our later work, At the same time, we should also pay attention to making reasonable choices based on the actual operating environment when using the product, to avoid the phenomenon of rework.