HDPE (High Density Polyethylene) marine sheet is a high-performance plastic sheet designed specifically for marine environments. With its excellent physical and chemical properties, it is widely used in shipbuilding, marine engineering, port facilities, and other fields.

1. Material characteristics

HDPE marine sheet is mainly made of high-density polyethylene (HDPE) and has the following core advantages:

·

Corrosion resistance: It has strong resistance to chemicals such as seawater, salt spray, acid, and alkali, and is suitable for long-term exposure to marine environments.

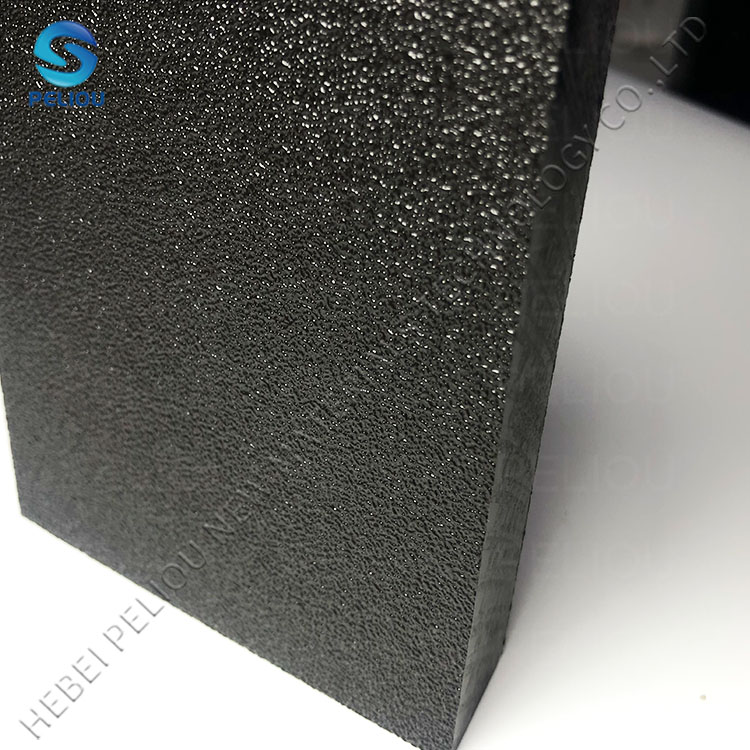

Impact resistance and wear resistance: The high tensile strength and surface hardness of HDPE (4-5 times that of LDPE) enable it to withstand mechanical stresses such as wave impact and ship friction.

Lightweight and environmentally friendly: low density (about 0.96 g/cm ³), lighter than water, easy to transport and install; At the same time, it can be recycled and meets environmental protection requirements.

Aging resistance and UV resistance: By adding antioxidants and UV absorbers, the service life in strong sunlight and extreme weather conditions has been extended.

2. Application scenarios

Typical uses of HDPE marine sheet in marine engineering include:

Ship deck and bulkheads: used to replace traditional wood or metal, reduce weight, and prevent rusting.

Wave barriers and buoys: their resistance to seawater erosion and impact make them suitable for port protection facilities.

Pier wharf deck: Anti slip surface design enhances safety while avoiding the problem of wood material decay.